- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

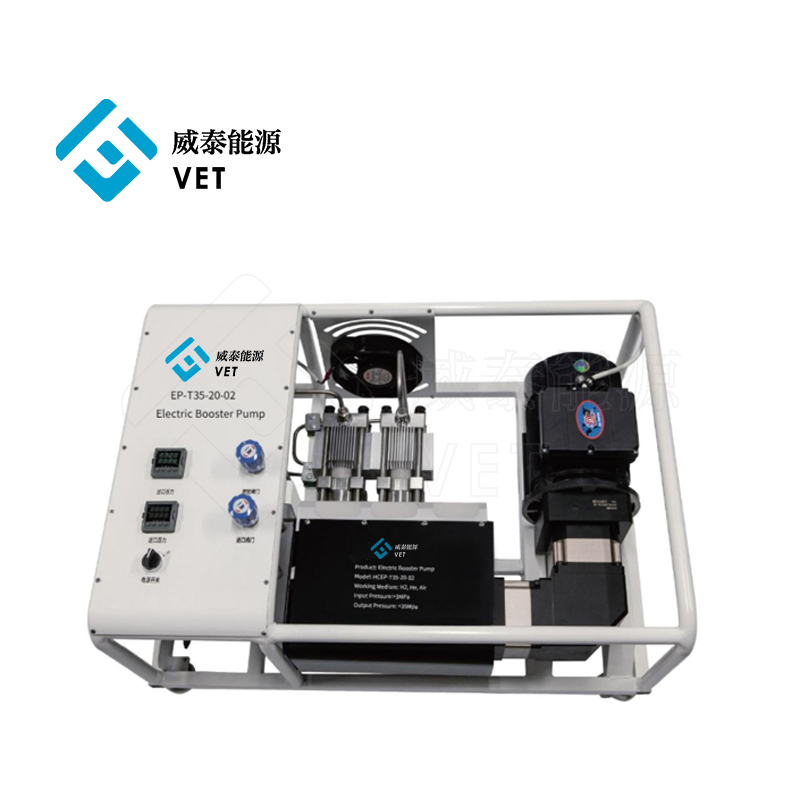

10-kilowatt water electrolysis hydrogen production test system

The 10-kilowatt water electrolysis hydrogen production test system from Semicera is designed for high-efficiency hydrogen generation through the innovative process of water electrolysis. This system offers advanced capabilities for producing clean, renewable hydrogen energy, making it an ideal solution for research and development or industrial applications.

Send Inquiry

CHINA-VET’s introduces the 10-kilowatt water electrolysis hydrogen production test system, a state-of-the-art apparatus engineered to optimize the hydrogen generation process through water electrolysis. This system is built with precision and reliability, featuring robust components that ensure consistent performance under various operational conditions. Its advanced design allows for high efficiency and purity in hydrogen production, significantly contributing to the reduction of carbon footprints and promoting sustainable energy solutions.

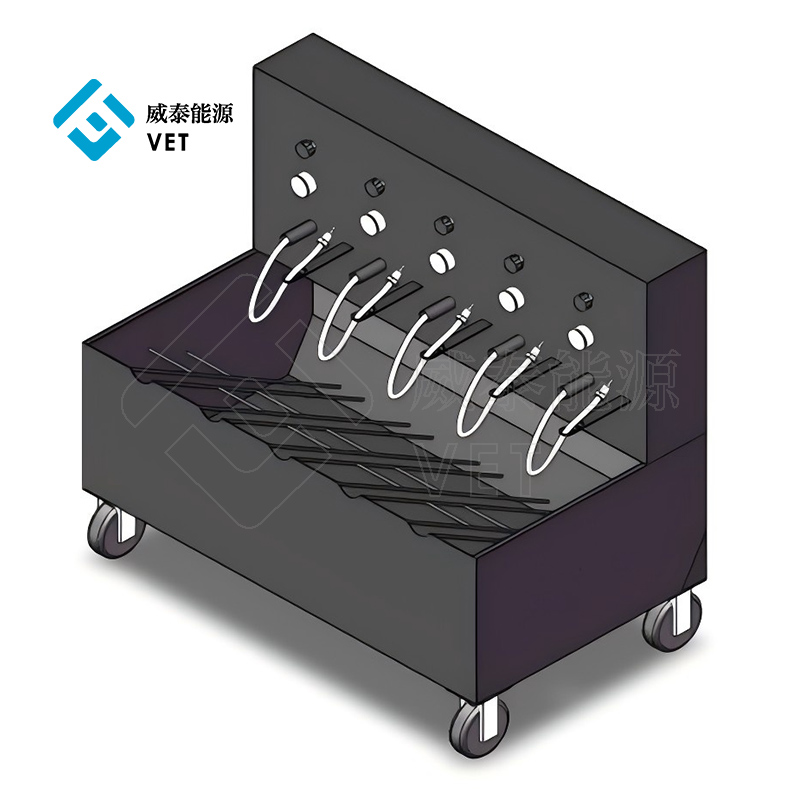

The system’s versatility and adaptability make it suitable for a wide range of applications, from industrial manufacturing to academic research. It comes with user-friendly interfaces and comprehensive monitoring systems that provide real-time data on production rates, purity levels, and operational parameters. With a capacity to produce up to 10 kilowatts of hydrogen energy, it offers a scalable solution for both small-scale testing and large-scale production scenarios.

In addition to its technical prowess, the 10-kilowatt water electrolysis hydrogen production test system is designed with safety and environmental considerations in mind. It incorporates multiple safety features to prevent overpressure, leakage, and other potential hazards, ensuring a secure operation at all times. Its eco-friendly design aligns with global efforts towards a cleaner, greener future, making it a valuable asset for any organization committed to sustainable practices.

Main features and functions:

1. 10 kW power: The system is designed to produce 10 kW of power, which can produce a certain amount of hydrogen and is suitable for medium-scale hydrogen production.

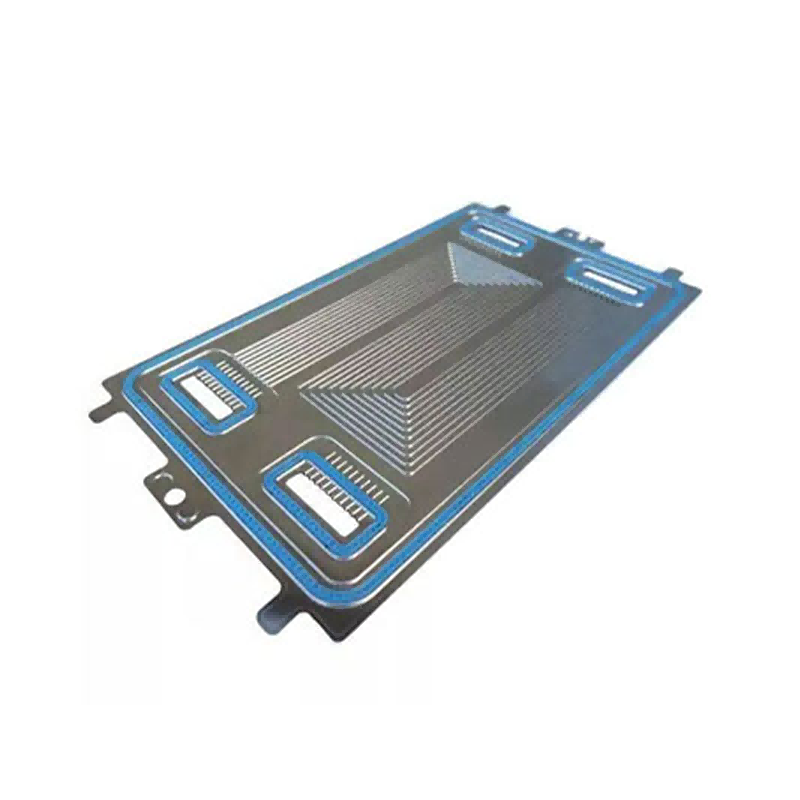

2. AEM technology: Water electrolysis is carried out using alkaline exchange membrane (AEM) technology, which uses ion exchange membranes with high alkalinity to achieve water electrolysis and produce pure hydrogen and oxygen.

3. Hydrogen production by water electrolysis: The system produces hydrogen by reacting water to decompose it into hydrogen and oxygen. This process is an environmentally friendly method to generate the required electricity from renewable energy or electricity.

4. Hydrogen production efficiency: The system can measure and record key parameters in the hydrogen production process to help evaluate the production and efficiency of hydrogen.

5. Data acquisition and control: The system is usually equipped with data acquisition and automatic control functions, which can monitor key parameters in real time and adjust operations according to set conditions to optimize hydrogen production efficiency.

6. Application areas: This system is usually used in laboratories, research institutions and industrial fields to study the efficiency and feasibility of water electrolysis hydrogen production technology.

7. Safety: Given the hydrogen production process involved, the system is usually designed with appropriate safety measures to ensure the safety of operators and equipment.

8. Sustainability: Using renewable or renewable energy as energy input, this system helps promote the development and application of sustainable energy technologies.

Product technical parameters

|

Rated hydrogen production rate |

2.3 Nm3/h |

|

Current density |

0.1~1.5A/cm2 |

|

Working current |

20~330A |

|

Working temperature |

Recommended 60~80C |

|

Electrolyte |

Recommended 1M KOH solution |

|

Electrolyte stack size |

220*260*400mm |

|

Electrolyte stack weight |

~75kg |

|

Working pressure |

1~3MPa |

|

Unit voltage |

1.6~1.9V |

|

Working stack pressure |

38~46V |

|

Input power |

0~12 kW |