- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

High Volume PEM Electrolyzer

VET Energy is one of the famous China High Volume PEM Electrolyzer manufacturers and suppliers. Our factory specializes in manufacturing of High Volume PEM Electrolyzer MEA. We stick to the principal of quality orientation and customer priority, we sincerely welcome your letters, calls and investigations for business cooperation.

Send Inquiry

VET Energy is a national high-tech enterprise specializing in the research and development, production, sales and service of hydrogen energy prdoucts, such as fuel cell stack, proton exchange membrane, membrane electrode assembly, bipolar plate, PEM eletrolyzer, hydrogen generator, fuel cell system, catalyst, BOP part and other accessories.

Over the years,passed ISO 9001:2015 international quality management system, we have gathered a group of experienced and innovative industry talents and R & D teams, and have rich practical experience in product design and engineering applications. we can customize the fuel cell according to each our customer’s requirements.

We will whole heartedly provide you with professional, excellent service and high-quality products with price advantages.

Why choose us?

1. Fast response, efficient communication

2. Quality consciousness, strict quality control

3. Timely delivery

4. After-sales services guaranteed

High Volume PEM Electrolyzer

1.Product Introduction

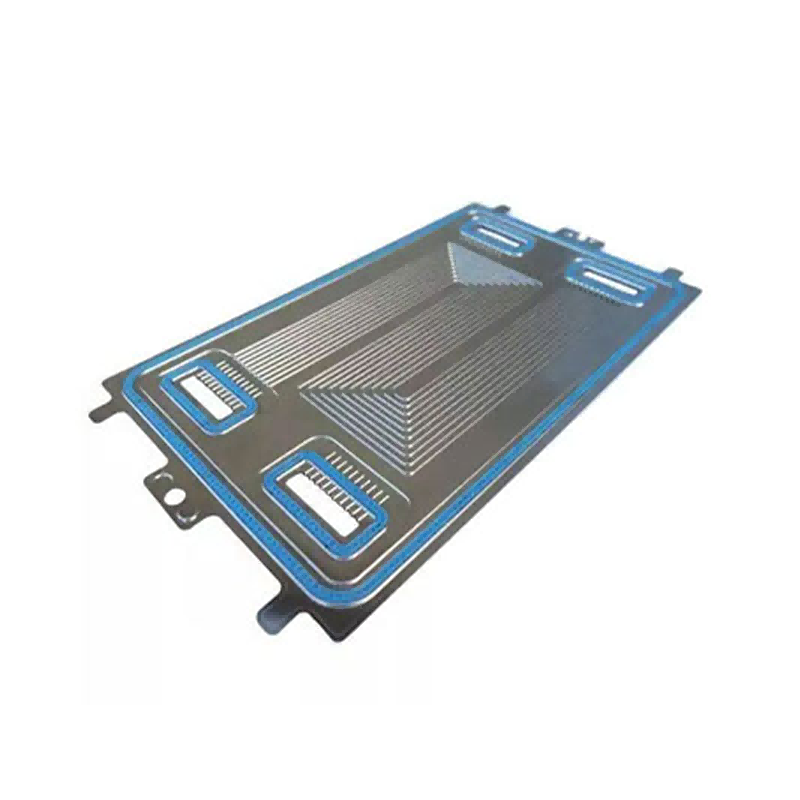

Hydrogen PEM electrolyser is an advanced patented product, which is light, highly effective, energy-saving and of environmental protection, producing hydrogen and oxygen through the electrolysis of pure water (without adding alkali). That's PEM technology.

Working Principle of PEM electrolyser hydrogen cell stack

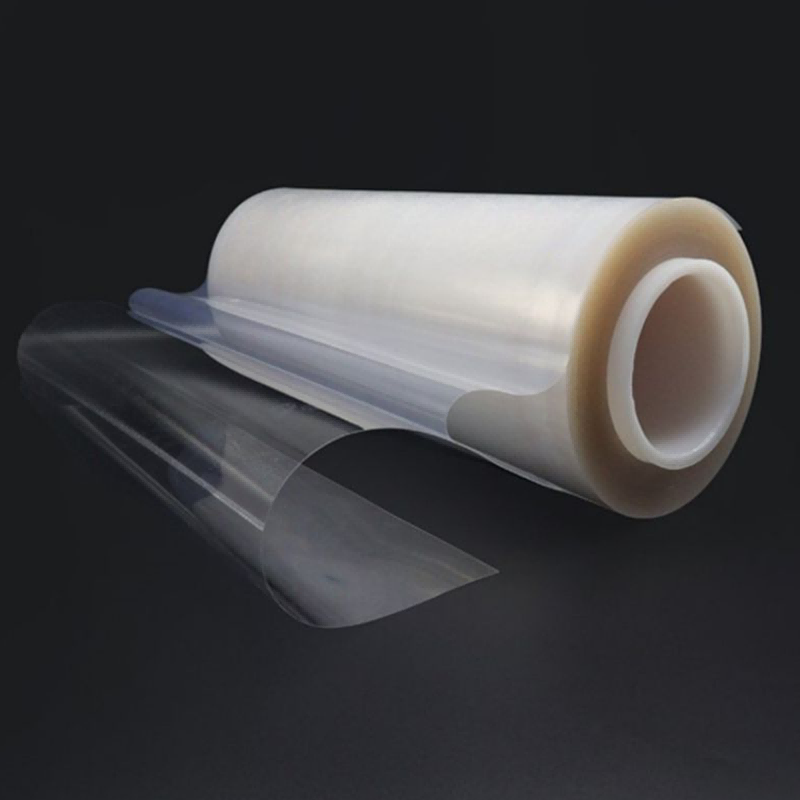

The proton exchange membrane (PEM), which only allows water and positive ions to cross between compartments. The membrane also serves as the electrolyte in the cell, eliminating the need for hazardous liquid electrolytes such as concentrated potassium hydroxide. PEM water electrolysis simply splits pure deionized water (H2O) into its constituent parts, hydrogen (H2) and oxygen (O2), on either side of this membrane. When a DC voltage is applied to the electrolyzer, water fed to the anode, or oxygen electrode, are oxidized to oxygen and protons, while electrons are released.

The protons (H+ ions) pass through the PEM to the cathode, or hydrogen electrode, where they meet electrons from the other side of the circuit, and are reduced to hydrogen gas. The two reactions that occur in the cell are as follows:

2.2H2O -> 4H+ + 4e- +O2

3.4H+ + 4e- -> 2H2

4.Thus, the only possible components of the streams are hydrogen, oxygen and water moisture, as shown in Figure 1 below.

2.Product Parameter

|

Model |

Unit |

PEM-150 |

PEM-300 |

PEM-600 |

PEM-1000 |

PEM-1500 |

PEM-2000 |

PEM-3000 |

PEM-8000 |

|

Cells |

- |

2 |

1 |

2 |

4 |

6 |

8 |

12 |

32 |

|

Stack Diameter |

mm |

85 |

138 |

138 |

138 |

138 |

138 |

138 |

138 |

|

H2 Flow Rate |

mL / min |

0-150 |

0-300 |

0-600 |

0-1000 |

0-1500 |

0-2000 |

0-3000 |

0-8000 |

|

O2 Flow Rate |

mL /min |

0-75 |

0-150 |

0-300 |

0-500 |

0-750 |

0-1000 |

0-1500 |

0-4000 |

|

Voltage |

V (DC) |

2-5 |

2-5 |

4-7 |

8-10 |

11-14 |

15-18 |

20-23 |

26-30 |

|

Max Input Current |

A (DC) |

20 |

40 |

40 |

40 |

40 |

40 |

80 |

120 |

|

Water Consumption Rate |

cc / hr |

12 |

18 |

36 |

60 |

60 |

60 |

90 |

120 |

|

Operating Temperature |

- |

5°C to 45°C |

|||||||

|

Output Pressure |

- |

0~1MPa |

|||||||

|

Membrane Type |

- |

Nafion PFSA |

|||||||

|

Sintered Titanium diffusion medium |

|||||||||

|

Precious metal electrode |

|||||||||

|

Need deionized or re-distilled water |

|||||||||

|

Water Resistivity: >1 MΩ*cm |

|||||||||

|

Water Conductivity: <1 us/cm |

|||||||||

|

Estimated Lifetime: If the water quality and power supply is always in ideal condition you can expect about 10,000 hours of operation. |

|||||||||

3.Product Feature And Application

Product Advantages:

-Produce hydrogen by electrolysis pure water(forbid add alkaline), no corrosion, no pollution, high hydrogen purity

- Low unit cell voltage, low electrolyzer cell resistance and no heat, long desiccant replacement cycle, hydrogen purity is high.

- Lower power consumption, higher electrolysis efficiency

- Zero pole distance, high activity PEM catalytic electrode group

-Excellent mass transfer, heat transfer chemical process performance repolarized multi-cell structure

- Electrochemical, corrosion resistance, resistance to passivation and other superior performance of the multi-polar electrolytic cell material selection

- Good sealing performance

Applications

Hydrogen/Oxygen Inhalation Machine

Hydrogen Water Machine

Hydrogen Generator

Laboratories

4.Product Details

Instructions:

Connect correctly as drawing, water enters from inlet 2 and flows out from outlet 1 to ensure electrolysis

fully watered and maintained for 2-3 minutes. The other side is the same operation, from the plug 4 fill

water. When hydrogen outlet #3 flow out water, simultaneously block #4 by plug, and maintain 2-3

minutes, and then power on, to start electrolytic hydrogen production.

Working principles:

Applications for hydrogen electrolyzer:

Welcome to visit our factory! We could supply customized product according to different technical demand.