- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Hydrogen Fuel Cells: Structure Technology and Market Outlook

2025-06-07

Power Generation Mechanism & System Structure

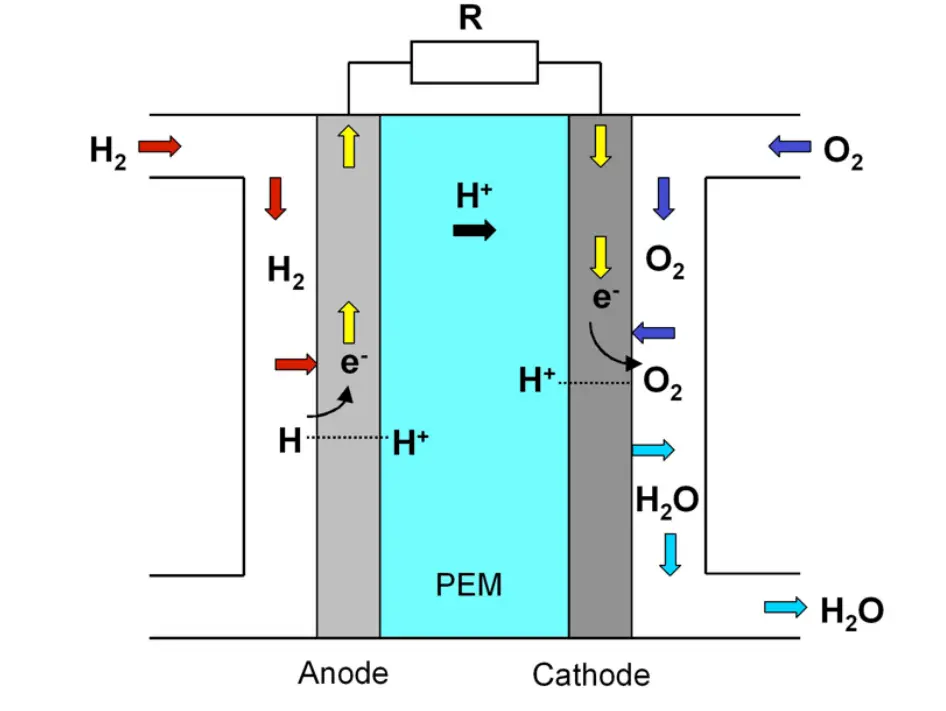

A hydrogen fuel cell stack is an electric power-generating device composed of multiple individual cells connected in series. Each cell includes an anode, cathode, and a proton exchange membrane (PEM).

During operation, hydrogen at the anode undergoes oxidation, while oxygen at the cathode is reduced. Protons pass through the membrane, generating an electric current without any combustion. This electrochemical process achieves an energy conversion efficiency of over 50%, significantly higher than conventional fuels.

Key components of a typical PEM fuel cell stack:

Membrane Electrode Assembly (MEA): The reaction core, consisting of the PEM, catalyst layers, and gas diffusion layers.

Bipolar Plates: Conduct electricity, distribute gases, provide mechanical support, and aid in heat management.

Sealing Gaskets: Ensure gas-tightness and support water management.

End Plates: Provide mechanical compression and integrate current collection.

Comparison of Main Fuel Cell TechnologiesCurrently, five major fuel cell technologies exist

PEMFC (Proton Exchange Membrane Fuel Cell):

Low operating temperature (60–80°C), fast start-up

Ideal for automotive and portable power

SOFC (Solid Oxide Fuel Cell):

High efficiency, operates at 600–1000°C

Suitable for stationary power generation

PAFC (Phosphoric Acid Fuel Cell):

Mature and commercialized

MCFC (Molten Carbonate Fuel Cell):

Compatible with multiple fuels

AFC (Alkaline Fuel Cell):

Early-stage technology, now largely phased out

Among these, PEM fuel cells dominate mobility applications due to their high power density and rapid dynamic response. Leading fuel cell vehicles like Toyota Mirai and Hyundai NEXO adopt PEMFC technology.

Hydrogen Production & Storage CostProduction

Production:

Most hydrogen today is produced from fossil fuels via Steam Methane Reforming (SMR)—a low-cost but high-emission method.

In contrast, green hydrogen generated by electrolysis using renewable energy is much cleaner but still comes at a higher cost.

Storage:

Compressed Hydrogen (350–700 bar) is common, though compression consumes energy.

Liquid Hydrogen requires cryogenic systems at –253°C.

Hydrogen Carriers like ammonia or LOHC offer alternatives but add operational complexity.

Safe and efficient storage and transportation remain a critical bottleneck for large-scale hydrogen deployment.

Regional Market AnalysisChina

China:

Strong government support and expanding FCEV pilot zones.

Japan:

Focused on home-use fuel cells and long-term national hydrogen strategies.

South Korea:

Investing in hydrogen mobility and nationwide infrastructure.

Europe:

Driven by the EU Green Deal, countries like Germany and the Netherlands are leading the shift toward green hydrogen and zero-emission transportation.

North America:

The Inflation Reduction Act (IRA) has significantly boosted U.S. and Canadian investments in hydrogen hubs and heavy-duty fuel cell applications.

Future Market Applications

According to the International Energy Agency (IEA), the global fuel cell market is projected to exceed $30 billion by 2030. Key application areas include:

Transportation – Trucks, ships, drones, and passenger vehicles

Distributed Power – Backup energy for data centers, hospitals, and telecom systems

Portable Power – Military and remote field operations

Energy Storage – Peak shaving and grid balancing when paired with renewables

Ready to Power the Clean Energy Future?Partner with VET ENERGY to lead the hydrogen transition.

Contact Us Now for a free consultation, sample request, or technical support