- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

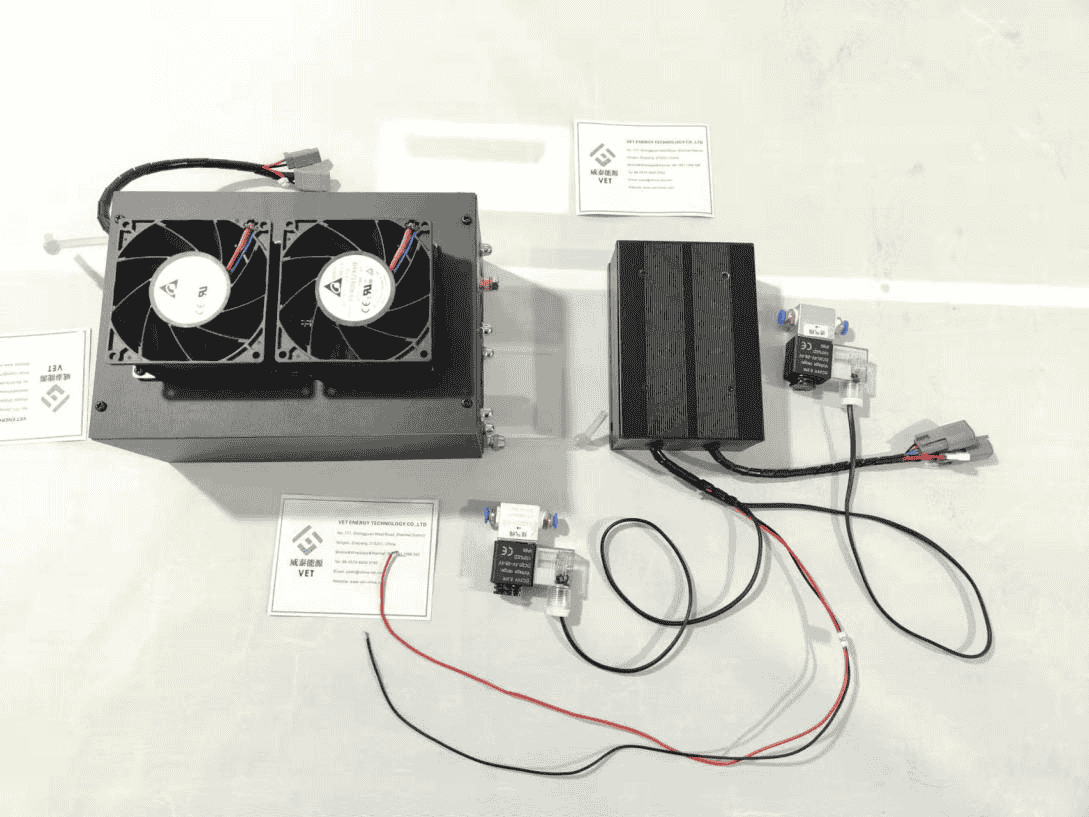

Fuel Cell Stack Construction Guide

2025-06-11

I. Core Components of a Fuel Cell Stack

A fuel cell stack is an energy conversion device composed of multiple single cells connected in series through bipolar plates. Its core components include:

Membrane Electrode Assembly (MEA): Consisting of a proton exchange membrane, catalyst layers, and gas diffusion layers.

Bipolar Plates: Commonly made of graphite or stainless steel, required to be both electrically conductive and corrosion-resistant.

Sealing System: Made of fluororubber or silicone, serving as a key component to ensure airtightness.

End Plates and Fastening System: Typically using aluminum alloy frames with hydraulic bolts.

II. Step-by-Step Construction Process

Stage 1: Initial Preparation

Determine the scale of the stack according to power requirements (typically 50–300 single cells).

Select the appropriate type of proton exchange membrane (Nafion series is commonly used for PEMFC).

Prepare a dedicated assembly platform (flatness deviation ≤ 0.05 mm/m²).

Stage 2: Membrane Electrode Processing

Catalyst Coating Process: Use ultrasonic spraying technology to evenly coat catalyst on both sides of the proton exchange membrane.

Hot Pressing: Laminate the anode, proton exchange membrane, and cathode into one complete MEA. Key parameters such as temperature, pressure, and time must be controlled during the hot pressing process.

Quality Inspection and Activation: Conduct electrical performance testing on the MEA, such as open-circuit voltage and polarization curves. Break-in activation may be performed to bring the MEA to its optimal state.

Packaging or Edge Treatment (optional): Apply edge sealing based on application needs to prevent gas leakage.

Stage 3: Bipolar Plate Processing

Flow field design should preferably adopt serpentine flow paths.

Graphite plate channel depth should be controlled between 0.8–1.2 mm.

Metal plates should undergo surface treatment such as gold plating or carbon coating.

Stage 4: Stack Assembly

Stack components in a "sandwich" structure in the following order: bipolar plate → sealing gasket → MEA → sealing gasket → bipolar plate.

Use an optical positioning system to ensure alignment error between layers is less than 0.1 mm.

Control final compression to 15–20% of the total stack thickness.

III. Key Quality Control Points

Gas tightness testing: Helium mass spectrometry leak rate must be less than 1×10⁻⁶ mbar·L/s.

Contact resistance testing: Interfacial resistance of each single cell should be less than 10 mΩ·cm².

Activation process: Perform 48-hour pre-activation using a stepwise voltage ramping method.

IV. Common Problem Solutions

Voltage imbalance: Check the uniformity of the flow field and distribution of compression force. Use pressure-sensitive film to analyze force distribution.

Abnormal water management: Adjust the cathode-side humidity (recommended 60–80% RH). Optimize the drainage channel design of the flow field.

VET ENERGY Technology Co., Ltd. focuses on the field of hydrogen energy technology, dedicated to providing global customers with high-performance fuel cells, electrolyzers, and core supporting components. With an experienced R&D team and proprietary core technologies, our products are widely applied in mobile energy, energy storage systems, and scientific research and education. Relying on excellent system integration capabilities, strict quality control, and flexible customization services, we continuously deliver efficient, safe, and sustainable hydrogen energy solutions to our customers.